Today, advanced planning and scheduling (APS) systems manage the complexities of manufacturing schedules.

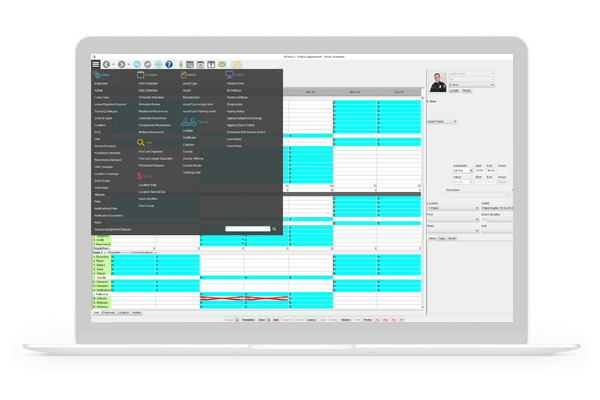

#Intime scheduling software

With just-in-time scheduling, production cycles can also be optimized so that companies enjoy greater productivity from their manufacturing facilities.Īs with other planning and scheduling tasks in manufacturing, the execution of just-in-time scheduling has evolved from a paper-based operation, to an application of general spreadsheet programs, to interactive software systems designed specifically for planning and scheduling. Manufacturers also cut costs associated with warehousing inventory or stockpiling materials along a production line. JIT scheduling is designed to avoid late deliveries on the one hand, and a backlog of materials, WIP and finished goods on the other.īy reducing backlogs and inventories, just-in-time scheduling helps companies reduce waste from expired or damaged materials. Just-in-time scheduling enables a manufacturer to adjust to last-minute changes, which may arise due to work order modifications, time overruns, material availability issues, and other factors. This same objective characterizes just-in-time planning, but the time horizon for JIT planning is weeks or months. Just-in-time scheduling is the means by which a manufacturer ensures, on a day-to-day basis, that each order is produced with just enough time to achieve on-time delivery. Although JIT production was conceived as a standalone methodology (about 50 years ago by the Toyota Motor Corporation), today it is typically considered one aspect of lean manufacturing. The primary goal of JIT production is to minimize the time between receiving supplies and delivering the finished product to the end customer. Just-in-time scheduling is one aspect of the general principle of just-in-time production.

Just-in-time (JIT) scheduling is a strategy designed to minimize the quantity of manufacturing work in progress (WIP) and inventories of raw materials and finished goods.

0 kommentar(er)

0 kommentar(er)